Taming the Wild BOM: Why You Need a PLM System to Corral Your Data

Learn why you need a PLM system to help corral your data in our latest blog.

This blog post explains how to change specific components in Autodesk Inventor instead of bulk editing every sheet metal component in the entire assembly.

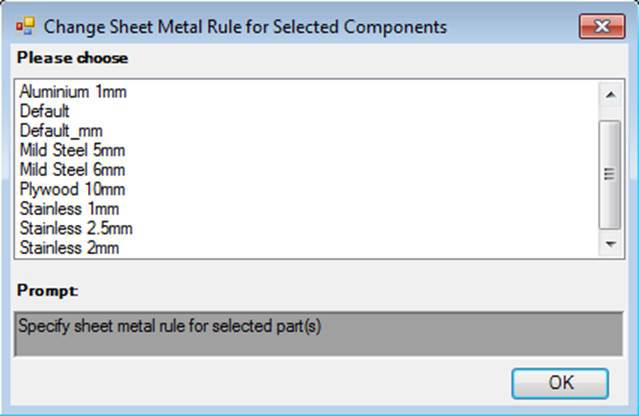

I previously posted some iLogic code to automatically change the sheet metal rule in every sheet metal component in the assembly. A forum user has requested the ability to pick specific components to change, instead of bulk editing every sheet metal component in the entire assembly.

Watch the video below to find out how to change specific components.

Note: the below video was created by Excitech prior to becoming Symetri in January 2021, following its acquisition by Addnode Group. All Excitech products, services and solutions mentioned in this recording are available through Symetri.

You can download the requested iLogic rule here.

If you’re interested in learning how the code works, please read below:

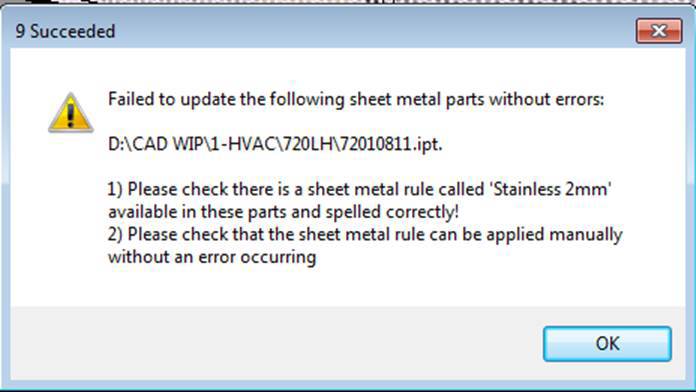

We can see that 9 components succeeded in the screenshot above, and 1 failed. Why would it fail?

The best thing to do is to manually open the component(s) that have failed and try applying the sheet metal rule manually – this will highlight what the issue is.

Explore the other features of Autodesk Inventor on our Inventor page.

Learn why you need a PLM system to help corral your data in our latest blog.

Learn about BIM to GIS Collaboration Patterns Between Owners, AEC Firms, and Municipalities in our most recent blog post.

Learn about the Dynamic Duo of Water Infrastructure Management through Autodesk’s InfoWater Pro and Esri ArcGIS in our most recent blog post.