Taming the Wild BOM: Why You Need a PLM System to Corral Your Data

Learn why you need a PLM system to help corral your data in our latest blog.

You’ve heard me talk about Fusion 360 and how Autodesk is adding more and more functionality to the product. In my upcoming blogs, I will dive deep into why Fusion 360 is such a disruptive technology on the market and why industry and educational institutions are becoming more interested in what Fusion 360 has to offer.

In this second blog, I will explain what Fusion 360 is and introduce the Simulation Workspace, Manufacture Workspace, Drawing Workspace and Electronics Workspace.

So, what is Fusion 360?

Fusion 360 is the first collaborative, cloud-enabled CAD, CAM, CAE, and 3D PCB design platform that allows designers and engineers across the industry to connect, collaborate and ultimately bring products to market faster than ever before.

The Simulation Workspace

The Fusion 360 Simulation Workspace allows Engineers to perform simulation studies of different FEA concepts on the design models. The following image is an overview of the types of study that can currently be generated:

These tools available in the preliminary design stage allow engineers to perform in-depth testing on the products during the design phase to help reduce errors and improve the product’s overall safety before the manufacturing process starts.

Fusion 360 users also have an advantage where you can import any native CAD file from any CAD package on the market and perform FEA tasks when required. Models can also be simplified in the Fusion Design or Simulation Environments that allow output to other third-party FEA tools that may be used in the design or quality departments, for example, ANYSYS, CFD etc.

The Manufacture Workspace

Fusion 360's Manufacture Workspace offers the CAM Engineer a comprehensive set of manufacturing setup options for Milling, Turning or Mill/Turn, Cutting, Additive, Inspection and Fabrication type workflows.

The types of toolpath strategies available include 2.5-Axis Machining, 3-Axis machining, 3+2 (5-Axis Positional) Machining and 5-Axis Simultaneous Machining techniques. Recent updates are incorporating high-end machining strategies such as Steep and Shallow finishing found in Autodesk Flagship CAM package PowerMill, including multi-axis capabilities and collision avoidance, strengthening the machining capabilities that Fusion 360 has to offer.

As the associative behaviour of Fusion 360, where changes are made in the Design Environment, is automatically updated and reflected in the Manufacturing environment meaning that CAM related rework to applied toolpath strategies is kept to a minimum and captured with the design change.

Autodesk Fusion 360 offers an excellent machining simulation environment allowing CAM Engineers to simulate their toolpaths. They can check for collisions and gouges. Adjustments can then be applied to the toolpath strategy to ensure a high level of safety before generating the NC code required to operate their expensive CNC machinery.

Autodesk gives users access to a free online library of generic post processors, machine simulation files and tooling libraries where all the big players in the CNC world are accommodated for. They are constantly updated with the new and required functionality, including new machines and post-processors being added regularly

If you are unable to locate the desired post processor and or machine simulation file, you have two options:

Option 1

Autodesk released instructions on manually creating and manipulating post processors, which can be found on the Post Library Website.

Option 2

Manufacturers can approach highly training Autodesk Partners, who are happy to take on post-processor development projects to get you up and running with the software by producing working post-processor and machine simulation files to suit your needs.

If you are looking at adopting Fusion 360 for manufacturing, exploring the Post Processor Library is the perfect place to start. You will be surprised to see so many post processors available for free. If you find a post relating to your CNC hardware, why not see if you can replicate the required toolpath strategies created with your current CAM solution?

Symetri offers excellent services to help you explore Fusion’s functionality and see if the adoption is right for you. We can take your models, apply toolpath strategies, and generate test code to see if further alignment is required for a working post-processor. We also offer comprehensive best-in-class training around all the CNC machining capabilities mentioned above.

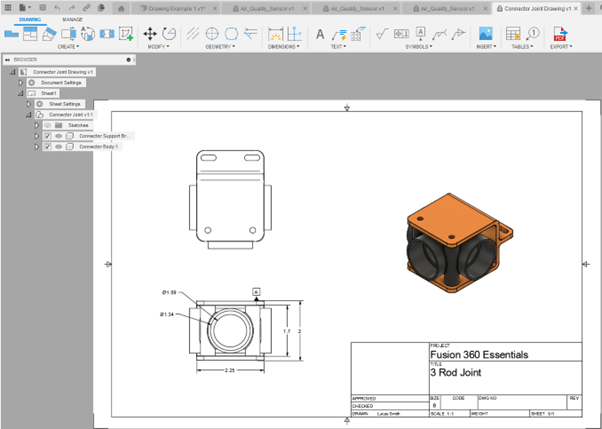

The Drawing Workspace

The Fusion 360 drawing workspaces allow engineers to create technical drawings based on their designs. With the associativity between designs in any project, changes made in the design workspaces are automatically reflected in the associated drawing.

As expected, drawings can be generated for parts and assemblies. Still, they can also be generated from a design or animation, making it easy to quickly support your manufacturing process with the correct technical documentation when required.

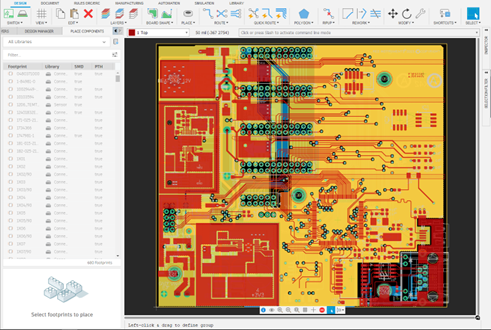

Electronics Design

Electrical Engineers have access to a comprehensive PCB Electronics design suite where combining model geometry designed in the Design Workspace and complex PCB layouts requirements can be created and incorporated into the live design.

Electronics Engineers can switch between PCB documents and Electrical Schematic and incorporate replicated and visible information between the different environments.

Electrical Engineers can generate electrical schematics relating to the PCB designs and automatically push to a 3D PCB layout that can be used to design the required housing, the ability to perform FEA simulations, and more.

So how can Symetri help you work smarter?

Industrial Training, Support and Mentoring:

Symetri offers a wide range of training courses, from Essentials Training to Advanced Multi Axis Machining training. These training courses are designed to get you up and running with the technology as quickly as possible. We understand that people come with different technical abilities, so laying the correct foundation in the learning process is key to how we conduct these training topics.

We also offer a Training Needs Assessment, where a highly skilled expert can conduct in-depth interviews with individual delegates to help them understand their current role, experience, and competencies. This allows us to evaluate and create a learning roadmap to ensure they are taught the correct subjects in the right order. This helps in retaining knowledge and building excellent customer relationships.

Symetri also offers unique support packages allowing engineers who are experiencing issues with software and workflow flexibility to log a support case and let our experts find a resolution to the problem.

Customers can also purchase project days that can be used for mentoring, where experienced product engineers can come and work alongside users helping them use Autodesk solutions on live jobs whilst passing on knowledge and experience, adopting the technology in a more streamlined approach.

Educational Institutions

Educational settings, including Secondary Schools, Colleges and Universities, can take advantage of fully funded onboarding sessions, where experienced Symetri Autodesk Certified Instructors will train and support teachers with the adoption process of the technology.

More and more educational settings are taking advantage of this service as Fusion 360 is taking the industry by storm due to its flexibility, versatility and further functionality being added regularly.

There is no need for lengthy product updates as the platform is cloud-based and only requires the user to restart the product once an update is available. These occur every 4 to 5 weeks, where improvements are constantly added based on user feedback and new expert functionality added to the core product or advanced user extensions. Preview features are also added to the product that the user can explore; the more people that use the preview feature, the more likely it will be added as a full feature in the future release.

My Conclusions.

So, whether you are an Educator, Product Designer, Mechanical Design Engineer, Electrical Engineer, Fabrication Engineer, CAM Engineer/CNC Programmer or Visualisation Expert, Fusion 360 has the required tools to design throughout each discipline. It allows you to collaborate intensely between departments and showcase the never-before-seen interconnectivity between each design and manufacturing stage. It effectively takes your new and existing products to market faster.

Want to learn more about Fusion 360 and its capabilities? Don’t hesitate to reach out and request further information from the Symetri team.

Learn why you need a PLM system to help corral your data in our latest blog.

Learn about BIM to GIS Collaboration Patterns Between Owners, AEC Firms, and Municipalities in our most recent blog post.

Learn about the Dynamic Duo of Water Infrastructure Management through Autodesk’s InfoWater Pro and Esri ArcGIS in our most recent blog post.