Taming the Wild BOM: Why You Need a PLM System to Corral Your Data

Learn why you need a PLM system to help corral your data in our latest blog.

I wrote a blog back in August 2018 about what users can expect from Fusion 360, three years on I am still excited about the future of this product but for a whole new reason.

So, did you challenge yourself to learn to use Fusion 360 back then?

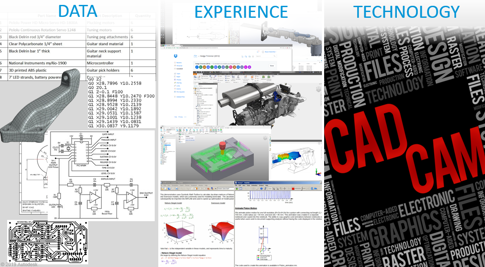

I did, I challenged myself to learn a new subject and Fusion 360 was the base I used to learn this. As a designer, I have always been interested in manufacturing. In my previous roles in industry, I always understood the importance of manufacturing but never thought about the challenges that manufacturing faced as I was so focused on design and engineering.

My understanding of manufacturing is still in its infancy, but I am growing in this area swiftly and the passion I have for this subject came from Fusion 360.

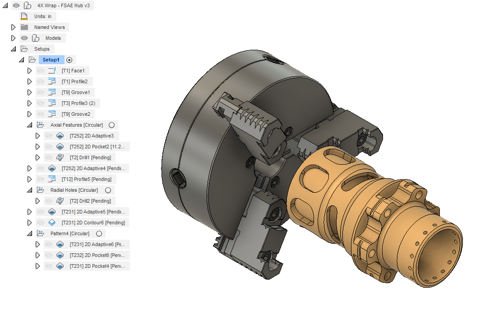

Fusion 360 presented a challenge to me, to learn how to create manufacturing toolpaths, which lead to an understanding of machining processes. In a short period of time, I have excelled in this subject and I know that other Fusion 360 users can do the same.

How many of us juggle multiple tasks daily, if I had advanced knowledge of manufacturing when I was in design and engineering, I may have designed differently, I would have been sympathetic towards manufacturing, I now appreciate the struggles that manufacturing has with design and engineering.

With the skills gap in manufacturing growing, I challenged myself to learn a new skill that way when I speak to my customers who are feeling they too have a skill shortage, I could help them understand my own struggles and successes.

Customers want to take advantage of all the products available to them in the Autodesk Product Design and Manufacturing Collection, therefore learning and development is key to opening new sustainable workflows through design, engineering and manufacturing.

Fusion 360 brings an integrated CAD/CAM workflow, as one single source that can be accessed anywhere. So, what does Autodesk Fusion 360 Manufacture have to offer out of the box?

2020 has shown us that we must learn to stay ahead as we venture into a new digital world. We must learn faster and digest more. To help this we need simple workflows supplied by simple applications, we don’t have time to learn using books and writing notes we never read again, we need smaller chunks of valuable information so we can get hands-on faster, take our products to market quicker and learn with confidence.

I have learned more in the last year than I did when I was studying at University, I think the reason for this is the accessibility that Fusion 360 gives.

As Autodesk updated their offerings for the advanced make applications my knowledge has increased further. Fusion with FeatureCAM and Fusion 360 with Powermill have opened a new level of manufacturing to me.

The parts of FeatureCAM and Powermill that help make quality parts and reduce cycle times has me now looking at parts and products in a whole new light.

Opened a can of worms really!

When was the last time you looked at your toolset and thought, are these tools still the right ones for the job? Can I venture into something new? As mentioned before, time is always a factor but with this said the longer you wait the more chance you will be left behind.

Be bold try something new?

Reach out to me for a chat, even if it is just to find out what Inventor CAM and Fusion 360 CAM can offer, or if you have a complex part that is causing you problems, we have a dedicated team at Symetri that can help with all things “MAKE”.

Learn why you need a PLM system to help corral your data in our latest blog.

Learn about BIM to GIS Collaboration Patterns Between Owners, AEC Firms, and Municipalities in our most recent blog post.

Learn about the Dynamic Duo of Water Infrastructure Management through Autodesk’s InfoWater Pro and Esri ArcGIS in our most recent blog post.